Providing a comprehensive and diverse range of high-quality steel structure design and manufacturing services from preliminary design and detailed planning to precision manufacturing.

Item No :

ZT-81068Order(MOQ) :

1 SetMain Materials :

Carbon Steel,Sandwich PanelCondition :

NewDesign Drawing :

ProvideApplication :

Steel Structural Fabrication ConstructionCustom Industrial Modular Prefabricated Pre Engineered Metal Steel Structural Workshop Construction

Quick Details:

| Keyword | Steel Structural Steel Frame Workshop, Light Steel Warehouse Workshop |

| Main Frame | Solid H-shape Steel Beam |

| Purlin | C.Z Shape Steel Channel |

| Window | Aluminium Window |

| Door | Sliding Door |

| Design Style | Industrial |

| Color | Customized Color |

| Drawing Design | AutoCAD PKPM 3D3S |

| Project Solution Capability | Graphic Design, 3D Model Design, Total Solution For Projects, Cross Categories Consolidation |

| After-sale Service | Online Technical Support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts |

Our steel structure workshop buildings are custom-designed to meet a variety of individual requirements. Should any provided example not align with your idea, even if it differs significantly, please rest assured. Whether it's prefabricated houses, warehouses, workshops, or any size of building—large, small, or multi-level—simply share the necessary data or building plans, and we'll promptly create a precise design, quotation, and rendering for you.

Our factory boasts over two decades of expertise in fabrication steel structures and construction, with our chief engineer bringing an additional 20 years of experience to the table.

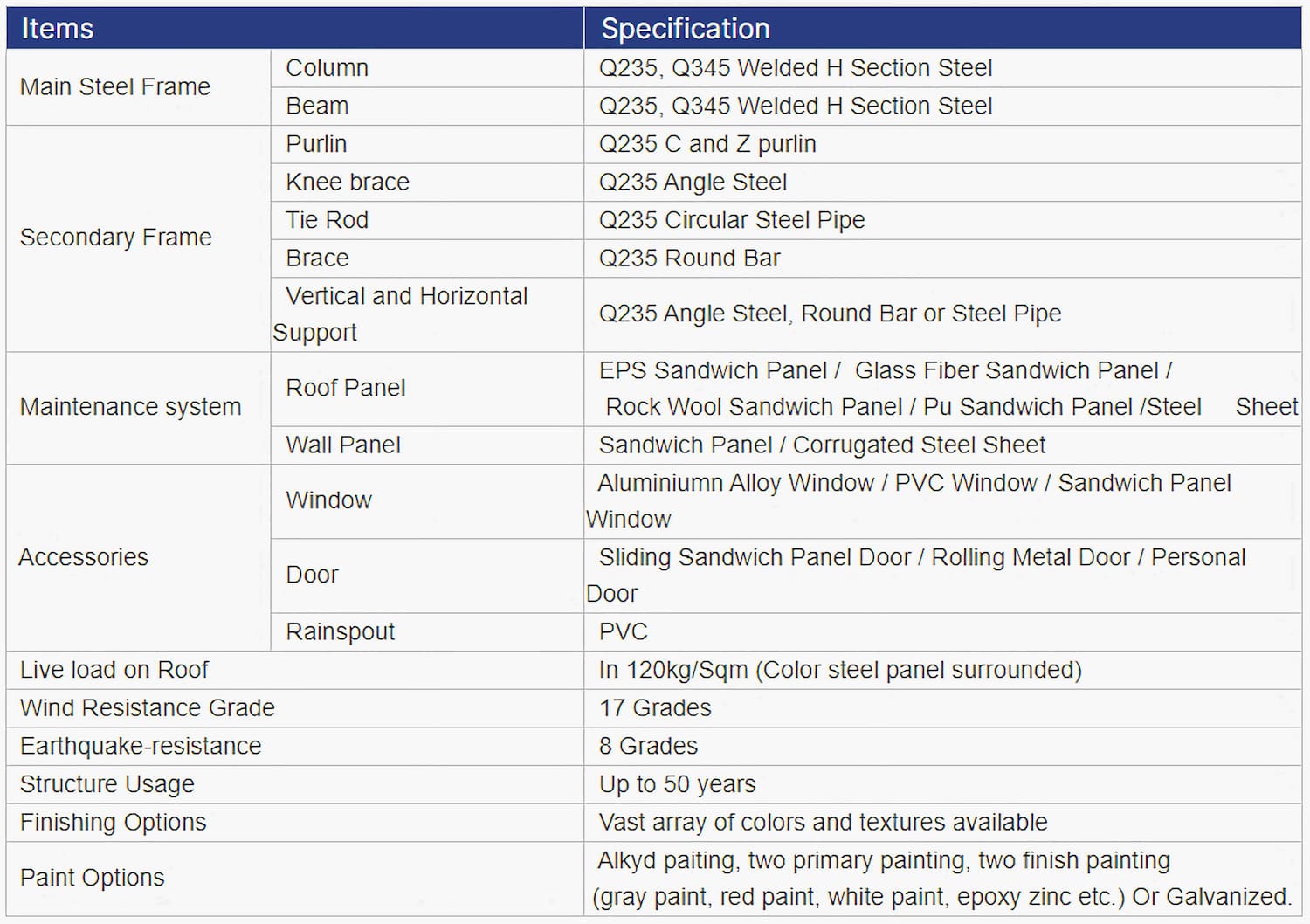

Component Parameter Of Prefabricated Steel Structure Workshop

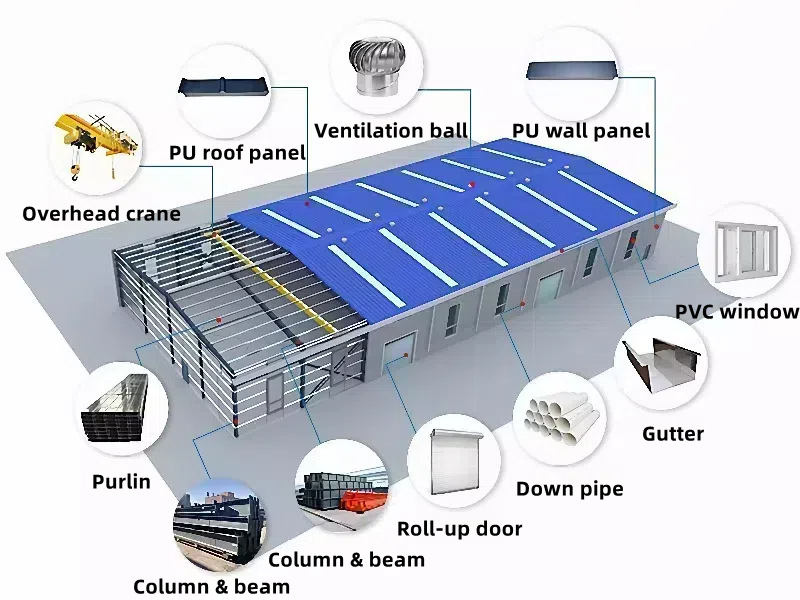

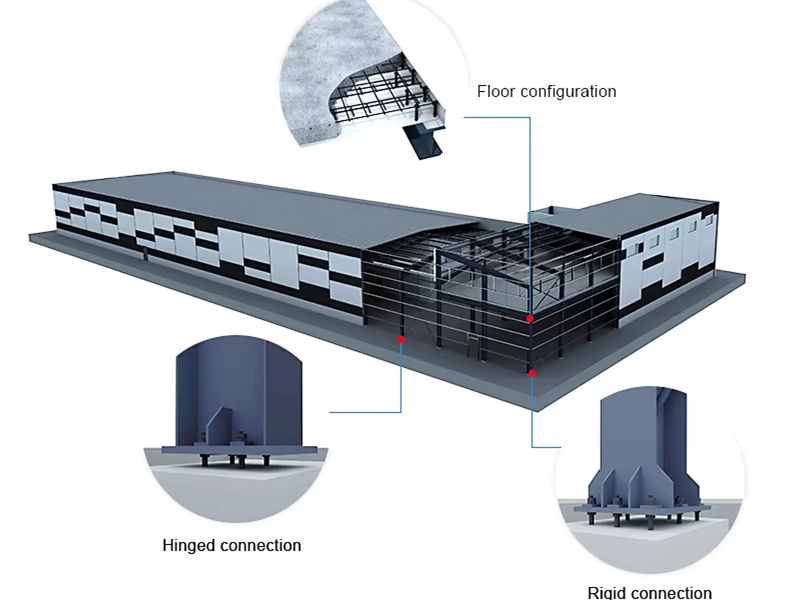

Prefabricated steel structure workshop are constructed using welded H-section steel for columns and beams, with some incorporating crane beams also made from H-section steel. The walls and roof are framed with galvanized C and Z-section steel purlins, and they are clad with metal sheets or sandwich panels. Entrances can be either electric shutter doors or sliding doors, while windows are made of PVC or aluminum. As steel frame structures become more prevalent, their benefits are becoming increasingly apparent when compared to traditional construction methods.

Design Capability For Prefabricated Steel Structure Workshop

Our seasoned design team excels in making steel structural designs that adhere to national and local standards, ensuring both structural integrity and cost-effective steel usage. All our projects are overseen by registered structural designers, capable of following BS, US, and international design codes. Additionally, we offer comprehensive services including detailing, 3D modeling, fabrication, and installation, all customized to specific project requirements.

|

|

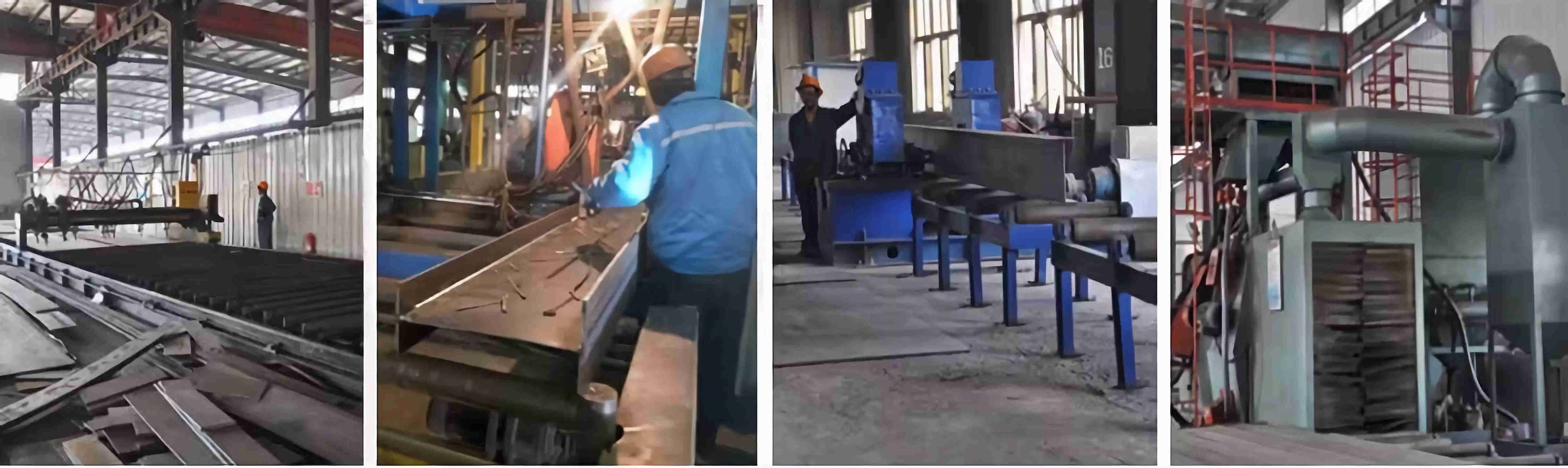

Producing Process Of Steel Framed Structure Workshop

At our factory, each component of the fabricated steel structure is produced according to the provided drawings and precisely to the specified dimensions. Our skilled team employs advanced equipment and techniques to ensure that every part meets the highest standards of quality and accuracy, reflecting our commitment to excellence in steel fabrication.

Packaging & Transportation

In our facility, we pack prefabricated steel building components according to their varying dimensions, optimizing space utilization to the fullest extent. To protect against damage during transit, we design and fabricate simple steel frames that securely hold each part in place, preventing any collision or impact that could occur during shipping.

Related Project For Steel Structure Buildings

Years of experience have enriched our portfolio with a multitude of successful steel structure projects across the globe. Our extensive track record is a testament to our expertise and commitment to delivering high-quality, innovative solutions that meet the diverse needs of our customers.

|

|

FAQ:

Q. What's the quality assurance you provided and how do you control quality of steel prefabricated buildings?

A. We have implemented a comprehensive quality control procedure that inspects our steel products at every phase of production. This includes the examination of raw materials, intermediate goods, materials that have undergone validation or testing, and final products, ensuring that each stage meets our standards for excellence in the steel construction industry.

Q. Do you offer guiding installation on site overseas for steel warehouse building?

A. Yes, we offer additional services including installation, supervision, and training. We can send our senior technical engineers to provide on-site supervision for installations abroad. Our team's expertise has been successfully applied in various countries, including Iraq, Dubai, South Africa, Algeria, and Ghana.

Q. What is your main market on construction of steel structure?

A. With a global perspective, our high-quality steel products and exceptional services have reached many countries and regions, including France, the UAE, Southeast Asia, and Africa, among others. We look forward to the opportunity to mutually beneficial business partnership with you in the near future

Q. How to pack the steel warehouse structure?

A. We use standard packaging materials for our steel structures. However, we are flexible and can accommodate special packaging requests as per your specifications. Please note that any additional costs incurred due to customized packaging solutions will be the responsibility of the customer.