Customized CNC Spare Parts Machining Services For Anodized Aluminum Stainless Steel Titanium Products

CNC machining fabrication refers to the process of using computer numerical control (CNC) machines to fabricate parts and components from raw materials. This process involves utilizing pre-programmed computer software to control the movement of machinery and tools, enabling precise and automated manufacturing.

Item No :

ZT-81030Range of Application :

Industrial EquipmentMain Materials :

Stainless Steel/ Aluminum/ Brass/ Copper/ Steel/ Titanium Alloy/ IronCondition :

NewLeading Time :

15-35 Days (Depend on the quantity)OEM Machining Metal Parts CNC Machining Service

Quick Details

Applicable: Industrial Equipment

Key Words: CNC Machining Works, CNC Custom Machining

Micro Machining: Provide

Material: Steel, Aluminum, Steel, Copper

Process: CNC Machining, Turning, Grinding, Wire-Cutting

Drawing Format: 2D/(PDF/CAD)3D(IGES/STEP

Certification: ISO 9001:2008

Tolerance: 0.01- +/-0.005mm

Service: One-Stop Service

Color:Customized Colors

Size: Customized Size\Client's Drawings

OEM/ODM: Accepted

CNC machining fabrication can encompass various techniques such as cutting, milling, turning, and drilling, and it is widely used in industries such as automotive, aerospace, and manufacturing for its ability to produce high-precision components with consistent quality.

Our Advantages of CNC Machining center:

1. Complex Designs: CNC machining can create intricate and complex part geometries that may be challenging to achieve with traditional manufacturing methods.

2. Efficiency: The automated nature of CNC machining increases production efficiency,reducing lead times and costs.

3. Versatility: CNC machines can work with various materials, from metals to plastics, and perform a wide range of operations like milling, turning, and drilling.

4. Precision: CNC machining ensures high precision and strict tolerances, reducing the possibility of human errors and producing high-quality and reliable components.

AVAILABLE MATERIAL OF CNC MACHINING WORKS

| Aluminum | AL6061, AL6063, AL6082, AL7075, AL5052, A380, etc |

| Copper | C11000, C12000, C22000, C26000, C28000, C36000 |

| Stainless Steel | 303, 304, 304L, 316, 316L, 410, 420, 430, etc |

| Steel | Mild Steel, Carbon Steel, 1018, 1035, 1045, 4140, 4340, 8620, XC38, XC48, E52100, Q235, SKD11, 35MF6Pb, 1214, 1215, etc |

| Titanium Alloy | TC1, TC2, TC3,TC4, etc |

| Iron | A36,45#, 1213, etc |

| Plastic | ABS, PC, PP, PE, POM, Delrin, Nylon, Teflon, PEEK, PEI, etc |

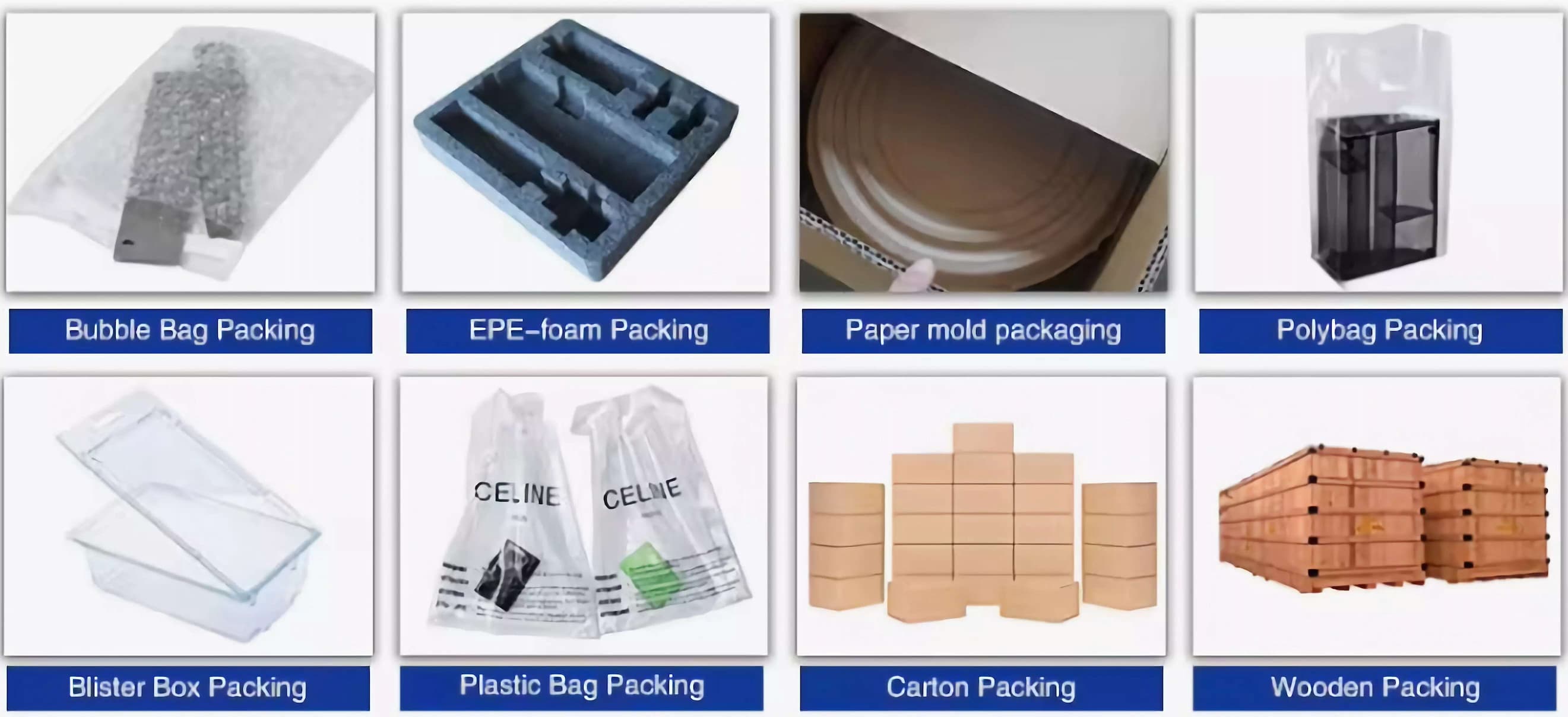

TRANSPORTATION AND PACKAGING OF CNC CUSTOM MACHINING PRODUCTS

We will choose the appropriate packaging and transportation methods according to the actual needs of customers.

FAQ

Q. What payment methods do we accept for CNC machining parts?

A. T/T, LC, Paypal, Credit Card and so on.

Q. What are the modes of transportation for CNC machining set?

A. Express, by SEA, by AIR, by Land transportation.

Q. How much do you charge for samples?

A. We accept the proof before mass production, the proof time depends on the ease of production of the product. Samples require a deposit or sample fee to be paid first, which will then be deducted on subsequent bulk orders.

Q. What is the ordering process for the product?

A. 1. Please tell us your demand and quantity of the products. 2. We make a quotation sheet according to your requirements to give you all the details of the order confirmation. 3. We arrange production after receiving your deposit or full payment. 4. When the goods are ready, we will take photos or video for you to check and ship as soon as possible.