The concrete mixing batching plant is an intelligent, automatic and environmentally friendly combined device used for centralized mixing of concrete.

Item No :

ZT-81060Order(MOQ) :

1 SetWarranty :

1 YearRange of Application :

Construction Works, Manufacturing Plant, Building Material ShopsKey Selling Points :

Concrete Mixing Plant, Electric, Automatic Control SystemCondition :

NewEasy Operation Mobile Mini Mixing Machine For Concrete Batching Plant

Key Words: Mini Batching Plant, Concrete Batching Mixing Plant, Hopper Batching Plant, Aggregate Mixing Plant

Quick Details:

| Product Name: | Concrete Mixing Plant |

| Dimension(L*W*H): | 17970*8500*15400 mm |

| Productivity: | 25-30 m3/ h |

| Power: | 60 KW |

| Power Type: | Electric |

| Mixer: | Twin Shaft Concrete Mixer |

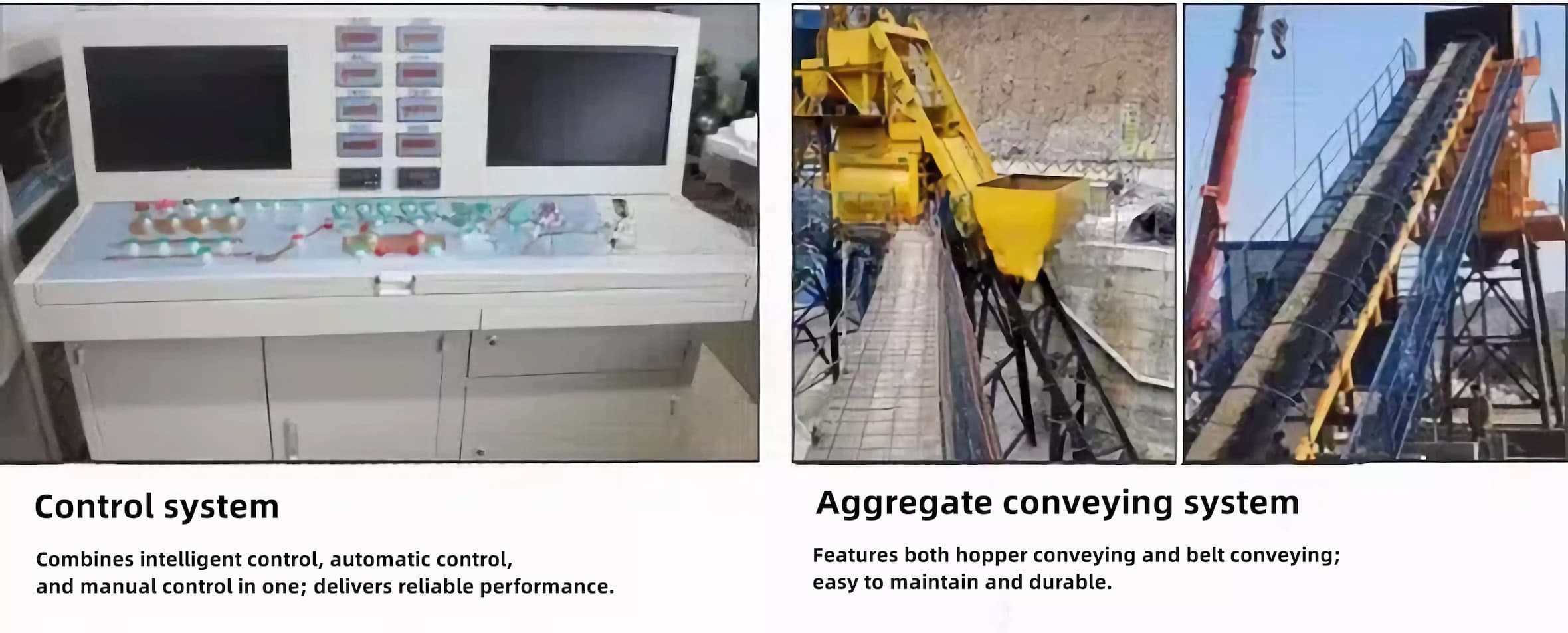

| Control System: | Automatic Control System |

| Discharging Height: | 3.8m |

| Warranty of core components: | 1 Year |

| Application: | Construction Industry |

| Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided |

The portable aggregate concrete mixing plant is primarily utilized in concrete construction projects, with its core function being the blending of concrete. This type of automatic aggregate concrete mixing batching plant is also known as a mobile compact concrete mixing plant. This series of commercial concrete mixing plants feature a modular design that is quick to assemble and widely appreciated globally. They incorporate high-efficiency and high quality mixing engines and operate with a dual-machine, dual-control microcomputer system. Additionally, these mini concrete batching plants are designed with noise reduction, dust control, and environmental protection in mind, making them a modern approach to cement concrete mixing equipment. Suitable for both urban and rural areas, these batching plants of concrete are ideal for producing ready-mixed concrete. They are also well-suited for large-scale infrastructure projects such as roads, bridges, water management systems, airports, and ports, where high standards for concrete quality are essential.

Technical Parameter Of Portable Aggregate Concrete Mixing Plant

| Model Parameter | ZT 25 | ZT 35 | ZT 50 | ZT 60 | ZT 90 | ZT 120 | ZT150 |

| Productivity (m3/h) | 25 | 35 | 50 | 60 | 90 | 120 | 150 |

| Mixer model | JS 500 | JS 750 | JS 1000 | JS 1000 | JS 1500 | JS 2000 | JS 3000 |

| Concrete (L) | 500 | 750 | 1000 | 1000 | 1500 | 2000 | 3000 |

| Batching machine model | PLD 800 | PLD 1200 | PLD 1600 | PLD 2400 | PLD 2400 | PLD 3200 | PLD 4800 |

| Feeding way | skip hopper | skip hopper | belt /skip hopper | belt /skip hopper | belt | belt | belt |

| Motor power (kw) | 18.5 | 30 | 18.5×2 | 18.5×2 | 18.5×2 | 37×2 | 55×2 |

| Cement soli (t) | 60/100 | 60/100 | 100 | 100 | 100 | 100 | 100 |

Product Detail Of Small Aggregate Concrete Mixing Plant

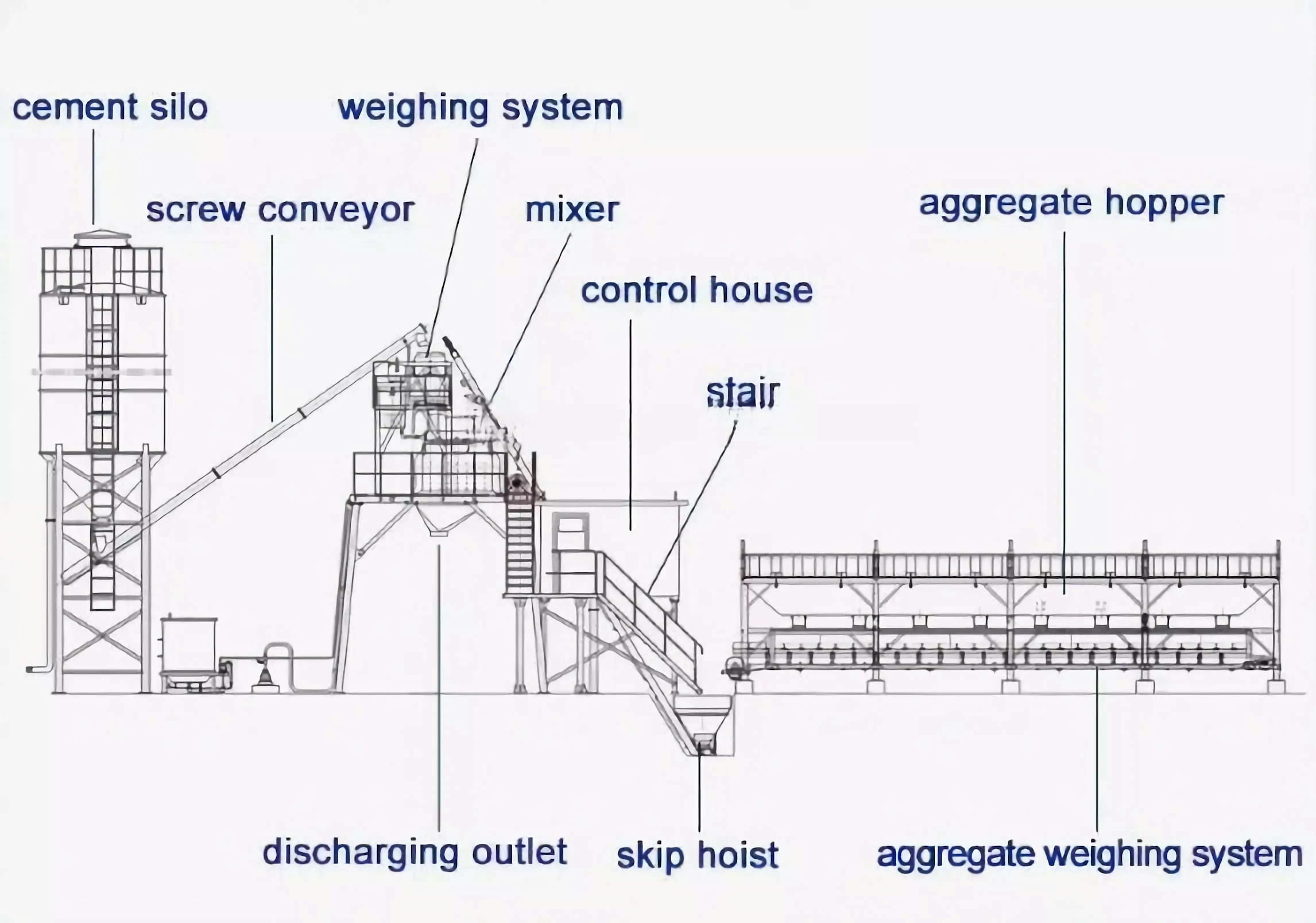

Design Drawing Of Aggregate Concrete Mixing Plant

We have an experienced design team that can tailor equipment plans and designs to meet the specific needs of our clients. We provide sound advice aimed at maximizing benefits and reducing costs for our clients.

Packaging and Transportation Of Small Batching Plant

We design packaging dimensions based on the size of the equipment selected by the customer, ensuring that the products can fit into containers and be transported via container shipping. Prior to dispatch, we carefully pack and secure the products to prevent damage during transit.

|

|

Our Service In Portable Aggregate Concrete Mixing Plant

Pre-sale Service

We provide a personalized service package that includes supplying technical parameters for related machinery, customizing factory layouts to fit customer space, and preparing formulations based on material costs. We also manufacture special machines to meet unique customer requests and offer expert advice on market trends, machinery operation, processing, materials, and packaging. Additionally, we assist with professional shipping agent recommendations or ship booking services as needed, ensuring a seamless and comprehensive support system for our customers.

After-sale Service

We offer a tailored service package to meet our clients' needs, including supplying allocation charts as per buyer requests, devising space-efficient equipment placement schemes based on the client's plant size, and providing a range of optional basic formulas. An operation manual is provided post-shipment to ensure smooth operation. Our commitment extends to a one-year warranty and lifetime maintenance, along with complimentary quick-wear parts and free training to support our clients throughout the lifecycle of the equipment.